Marketing Materials

Click to Download

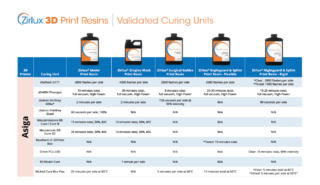

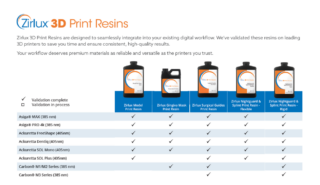

Validated Curing Units for Zirlux 3D Print Resins

Validated Printers for Zirlux 3D Print Resins

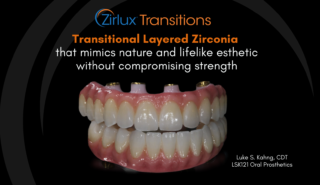

Zirlux Transitions Brochure

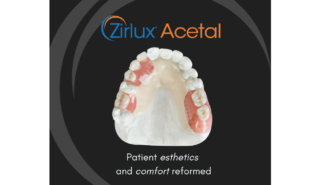

Zirlux Acetal Clinical Brochure

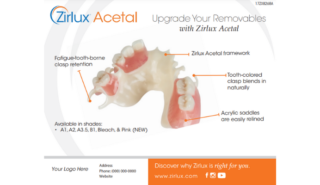

Zirlux Acetal Benefits Case Stuffer

Zirlux 16+ Case Stuffer

Zirlux Anterior Multi Case Stuffer

Zirlux Acetal Case Stuffers

Zirlux Materials Brochure

Zirlux Anterior Multi Sintering & Finishing Guidelines

Zirlux 16+ Sintering Instructions for Use

Zirlux 16+ Sintering Guidelines

Zirconia Finishing Guidelines

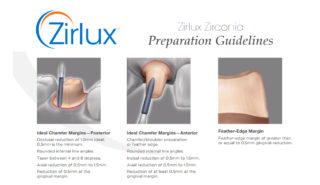

Zirlux Zirconia Preparation Guidelines